|

| May 22, 2012 | Volume 08 Issue 20 |

Materials News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Weird stuff: Moon dust simulant for 3D printing

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Learn more.

Make nylon 3D-printed prototypes and parts in the office

The new SLS 300 from 3D Systems is an affordable, turnkey, closed-loop 3D-printing system designed to operate in a smaller-footprint environment. SLS 300 makes selective laser sintering available to a broader range of customers with a high-reliability, affordable solution to produce end-use parts. Users can produce tough, durable parts from a range of production-grade nylon materials. Amazing fill, finishing, and clean-up systems.

The new SLS 300 from 3D Systems is an affordable, turnkey, closed-loop 3D-printing system designed to operate in a smaller-footprint environment. SLS 300 makes selective laser sintering available to a broader range of customers with a high-reliability, affordable solution to produce end-use parts. Users can produce tough, durable parts from a range of production-grade nylon materials. Amazing fill, finishing, and clean-up systems.

Learn more.

Will it erode? 3D-printing materials comparison from Xometry

Which 3D-printed plastics are the toughest? In this "Will it ..." video, Greg Paulsen, Xometry's Director of Application Engineering, 3D printed Benchies (3D test models) using different materials (such as polycarbonate, PLA, polypropylene, ULTEM, and Nylon 11 and 12) and processes (such as FDM, SLS, MJF, SLA, LSPc, Polyjet, and DLS) and then ran several abrasion tests on them. Watch to find out which 3D-printed plastic is truly the toughest of them all!

Which 3D-printed plastics are the toughest? In this "Will it ..." video, Greg Paulsen, Xometry's Director of Application Engineering, 3D printed Benchies (3D test models) using different materials (such as polycarbonate, PLA, polypropylene, ULTEM, and Nylon 11 and 12) and processes (such as FDM, SLS, MJF, SLA, LSPc, Polyjet, and DLS) and then ran several abrasion tests on them. Watch to find out which 3D-printed plastic is truly the toughest of them all!

View Part 1.

View Part 2.

Graphene Handbook: Learn all about this wonder material

Metalgrass LTD has published the 11th edition of its "Graphene Handbook," a comprehensive resource on graphene technology, the industry, and the market for this wonder material made of single layers of atoms of pure carbon. The book includes development history, production methods, current research, an intro to metrology and standardization, and even an investment guide. Under 100 bucks for digital edition. Hard copy available too.

Metalgrass LTD has published the 11th edition of its "Graphene Handbook," a comprehensive resource on graphene technology, the industry, and the market for this wonder material made of single layers of atoms of pure carbon. The book includes development history, production methods, current research, an intro to metrology and standardization, and even an investment guide. Under 100 bucks for digital edition. Hard copy available too.

Learn more.

Who knew? How colorants affect plastic

In plastic injection molding, one aspect of polymer characteristics that doesn't always get the consideration it deserves is the addition of colorant. Believe it or not, there is a whole scientific body of knowledge about the ways in which adding color to plastic can affect its behavioral properties. This short article by Denny Scher of ICO Mold takes a high-level look at some of the different, and surprising, ways colorants can affect plastics.

In plastic injection molding, one aspect of polymer characteristics that doesn't always get the consideration it deserves is the addition of colorant. Believe it or not, there is a whole scientific body of knowledge about the ways in which adding color to plastic can affect its behavioral properties. This short article by Denny Scher of ICO Mold takes a high-level look at some of the different, and surprising, ways colorants can affect plastics.

Read the full article.

Retaining magnets from JW Winco: Universal and clever

JW Winco has expanded its magnet line to support more applications with new materials, shapes, systems, and even raw magnets. Learn about their latest offerings, including retaining magnets designed for corrosive environments (GN 50.8), encapsulated magnets designed for sensitive or painted surfaces (GN 51.8), handle magnets (GN 53.3), and powerful magnets designed to handle challenging environs (GN 52.6).

JW Winco has expanded its magnet line to support more applications with new materials, shapes, systems, and even raw magnets. Learn about their latest offerings, including retaining magnets designed for corrosive environments (GN 50.8), encapsulated magnets designed for sensitive or painted surfaces (GN 51.8), handle magnets (GN 53.3), and powerful magnets designed to handle challenging environs (GN 52.6).

Learn more.

3D print tool steel with the ease of a plastic

The Virtual Foundry, a pioneer in advanced 3D-printing materials, is excited to announce the launch of their latest innovation: M300 Tool Steel Filamet™ (not a typo). This material answers the demand for FFF 3D-printable Tool Steel, delivering unparalleled strength and versatility. What sets this material apart is its seamless compatibility with various 3D printers, including Creality, Bambu Lab, Ultimaker, and more. The filament prints effortlessly, resembling the ease of working with PLA (plastic).

The Virtual Foundry, a pioneer in advanced 3D-printing materials, is excited to announce the launch of their latest innovation: M300 Tool Steel Filamet™ (not a typo). This material answers the demand for FFF 3D-printable Tool Steel, delivering unparalleled strength and versatility. What sets this material apart is its seamless compatibility with various 3D printers, including Creality, Bambu Lab, Ultimaker, and more. The filament prints effortlessly, resembling the ease of working with PLA (plastic).

Learn more.

Great Resources: Sheet metal design guide

If you're looking for a basic guide to sheet metal design, this one from Xometry will serve your needs well. Follow the design requirements and tolerances in this guide to ensure parts fall closer to design intent. This is the type of information you'll sock away and then refer to again and again.

If you're looking for a basic guide to sheet metal design, this one from Xometry will serve your needs well. Follow the design requirements and tolerances in this guide to ensure parts fall closer to design intent. This is the type of information you'll sock away and then refer to again and again.

Read the full article.

Particle foam perfectly distributed thanks to simulation with Ultrasim

BASF's Ultrasim simulation solution now includes Infinergy, an expanded thermoplastic polyurethane (E-TPU) that is used in a wide range of applications to make components with particle foam -- from bicycle tires to the soles on shoes. Identify and solve problems related to pneumatic filling when distributing particle foams in molds, even taking gravity and mold closing into consideration. Avoid those pesky air pockets.

BASF's Ultrasim simulation solution now includes Infinergy, an expanded thermoplastic polyurethane (E-TPU) that is used in a wide range of applications to make components with particle foam -- from bicycle tires to the soles on shoes. Identify and solve problems related to pneumatic filling when distributing particle foams in molds, even taking gravity and mold closing into consideration. Avoid those pesky air pockets.

Learn more.

Premium polymer DLP printer is half the price of its predecessor

Desktop Metal has just launched the ETEC Pro XL -- a premium polymer digital light processing (DLP) printer that enters the market at less than half the price as its predecessor. DLP is regarded by many as a superior polymer 3D-printing technology for speed, surface finish, and accuracy. Ideal for automotive and machine parts, aerospace components, housings, connectors, jigs and fixtures, short-run molds, and more.

Desktop Metal has just launched the ETEC Pro XL -- a premium polymer digital light processing (DLP) printer that enters the market at less than half the price as its predecessor. DLP is regarded by many as a superior polymer 3D-printing technology for speed, surface finish, and accuracy. Ideal for automotive and machine parts, aerospace components, housings, connectors, jigs and fixtures, short-run molds, and more.

Read the full article.

CNC machining case study: One-of-a-kind computer chassis

Learn how Josh Sniffen, the YouTuber behind the popular PC-building channel "Not From Concentrate," trusted Xometry to provide a wide range of manufacturing options, personalized Design for Manufacturing (DFM) feedback, and order management support for his latest creation: the HEXO ATX computer chassis. All in all, Sniffen procured parts using Xometry's CNC machining service, selective laser sintering 3D-printing service, and sheet metal cutting and fabrication services. A neat insider look at the process.

Learn how Josh Sniffen, the YouTuber behind the popular PC-building channel "Not From Concentrate," trusted Xometry to provide a wide range of manufacturing options, personalized Design for Manufacturing (DFM) feedback, and order management support for his latest creation: the HEXO ATX computer chassis. All in all, Sniffen procured parts using Xometry's CNC machining service, selective laser sintering 3D-printing service, and sheet metal cutting and fabrication services. A neat insider look at the process.

Read this Xometry case study.

Which parts should be 3D printed? AI combs through CAD files to find out

One of the biggest challenges in transitioning to additive manufacturing (AM) is the ability to identify which parts are best suited for the process quickly and easily. Learn how Danfoss, Stanley Engineered Fastening, and even the U.S. military have utilized advanced additive manufacturing software to automate the process, reducing material waste and energy costs, improving part reliability, decreasing lead times, as well as now having the ability to identify part consolidation opportunities through intelligent AM decision-making.

One of the biggest challenges in transitioning to additive manufacturing (AM) is the ability to identify which parts are best suited for the process quickly and easily. Learn how Danfoss, Stanley Engineered Fastening, and even the U.S. military have utilized advanced additive manufacturing software to automate the process, reducing material waste and energy costs, improving part reliability, decreasing lead times, as well as now having the ability to identify part consolidation opportunities through intelligent AM decision-making.

Read the full article.

9 key design tips for injection molding

Keep costs down and quality up all while optimizing your injection molded designs with these helpful tips from Xometry. Learn how to build better injection molded parts and products -- using draft angles, ribs and gussets, radii, fillets, and more -- and set expectations for the injection molding process. Good info here.

Keep costs down and quality up all while optimizing your injection molded designs with these helpful tips from Xometry. Learn how to build better injection molded parts and products -- using draft angles, ribs and gussets, radii, fillets, and more -- and set expectations for the injection molding process. Good info here.

View the video.

Metal additive manufacturing: Rocket turbopump design

Mixing undergraduate curiosity and real-world engagement, two students from Colorado University Boulder Aerospace Engineering Sciences program, Zachary Lesan and Patrick Watson, started an independent effort on turbopump design and manufacture that is a lesson in determination and industry collaboration. With lots of supplies and advice from industry heavy hitters including Velo3D, CFturbo, SpaceX, and many more, their project has reinforced significant points being made about next-generation rocketry.

Mixing undergraduate curiosity and real-world engagement, two students from Colorado University Boulder Aerospace Engineering Sciences program, Zachary Lesan and Patrick Watson, started an independent effort on turbopump design and manufacture that is a lesson in determination and industry collaboration. With lots of supplies and advice from industry heavy hitters including Velo3D, CFturbo, SpaceX, and many more, their project has reinforced significant points being made about next-generation rocketry.

Read the full article.

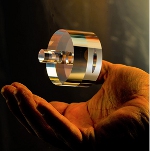

Transparent ceramics for extreme optics

Sapphire is an inherently transparent ceramic material that is resistant to extremes of temperature and environment. Sapphire can be processed to unique and precise shape/form by diamond grinding and polishing to allow full transparency. INSACO is a global leader in this capability -- and working with ultra-hard materials in general.

Sapphire is an inherently transparent ceramic material that is resistant to extremes of temperature and environment. Sapphire can be processed to unique and precise shape/form by diamond grinding and polishing to allow full transparency. INSACO is a global leader in this capability -- and working with ultra-hard materials in general.

Learn more.

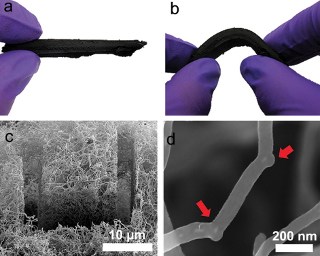

Nanotube 'sponge' has great potential in oil-spill cleanup

A carbon nanotube sponge that can soak up oil in water with unparalleled efficiency has been developed with help from computational simulations performed at the Department of Energy's (DOE's) Oak Ridge National Laboratory (ORNL).

Carbon nanotubes, which consist of atom-thick sheets of carbon rolled into cylinders, have captured scientific attention in recent decades because of their high strength, potential high conductivity, and light weight. But producing nanotubes in bulk for specialized applications was often limited by difficulties in controlling the growth process as well as dispersing and sorting the produced nanotubes.

A carbon nanotube sponge developed with help from ORNL researchers holds potential as an aid for oil-spill cleanup. Simulations at ORNL explained how the addition of boron atoms encouraged the formation of "elbow" junctions (seen in d) that help the nanotubes grow into large spongelike clumps (seen in a-c). The material is extremely efficient at absorbing oil in contaminated seawater because it attracts oil and repels water.

ORNL's Bobby Sumpter was part of a multi-institutional research team that set out to grow large clumps of nanotubes by selectively substituting boron atoms into the otherwise pure carbon lattice. Sumpter and Vincent Meunier, now of Rensselaer Polytechnic Institute, conducted simulations on supercomputers, including Jaguar at ORNL's Leadership Computing Facility, to understand how the addition of boron would affect the carbon nanotube structure.

"Any time you put a different atom inside the hexagonal carbon lattice, which is a chicken wire-like network, you disrupt that network because those atoms don't necessarily want to be part of the chicken wire structure," Sumpter says. "Boron has a different number of valence electrons, which results in curvature changes that trigger a different type of growth."

Simulations and lab experiments showed that the addition of boron atoms encouraged the formation of so-called "elbow" junctions that help the nanotubes grow into a 3-D network. The team's results are published in Nature Scientific Reports.

"Instead of a forest of straight tubes, you create an interconnected, woven sponge-like material," Sumpter says. "Because it is interconnected, it becomes three-dimensionally strong, instead of only one-dimensionally strong along the tube axis."

Further experiments showed the team's material, which is visible to the human eye, is extremely efficient at absorbing oil in contaminated seawater because it attracts oil and repels water.

"It loves carbon because it is primarily carbon," Sumpter says. "Depending on the density of oil to water content and the density of the sponge network, it will absorb up to 100 times its weight in oil."

The material's mechanical flexibility, magnetic properties, and strength lend it additional appeal as a potential technology to aid in oil-spill cleanup, Sumpter says.

"You can reuse the material over and over again because it's so robust," he says. "Burning it does not substantially decrease its ability to absorb oil, and squeezing it like a sponge doesn't damage it either."

The material's magnetic properties, caused by the team's use of an iron catalyst during the nanotube growth process, means it can be easily controlled or removed with a magnet in an oil cleanup scenario. This ability is an improvement over existing substances used in oil removal, which are often left behind after cleanup and can degrade the environment.

The experimental team has submitted a patent application on the technology through Rice University. The research is published as "Covalently bonded three-dimensional carbon nanotube solids via boron induced nanojunctions," and is available online here.

The research team included researchers from ORNL, Rice University; Universidade de Vigo, Spain; Rensselaer Polytechnic Institute; University of Illinois at Urbana-Champaign; Instituto de Microelectronica de Madrid, Spain; Air Force Office of Scientific Research Laboratory; Arizona State University; Universite Catholique de Louvain, Belgium; The Pennsylvania State University; and Shinshu University, Japan.

The work was supported by the National Science Foundation, the U.S. Air Force Office of Scientific Research, the U.S. Army Research Laboratory, and by the DOE Office of Science through ORNL's Center for Nanophase Materials Sciences (CNMS) and the laboratory's Leadership Computing Facility.

Source: ORNL

Published May 2012

Rate this article

View our terms of use and privacy policy